BEIJING, Oct. 24 (Xinhua) — Chinese scientists have recently made significant advances in overcoming critical obstacles in solid-state batteries, pushing their performance to new heights.

Solid-state batteries, widely regarded as the next generation of lithium battery technology, hold promising potential for applications in new energy vehicles and low-altitude aviation.

Previously, a 100-kilogram battery could power a vehicle for about 500 kilometers, but recent breakthroughs promise to extend that range beyond 1,000 kilometers.

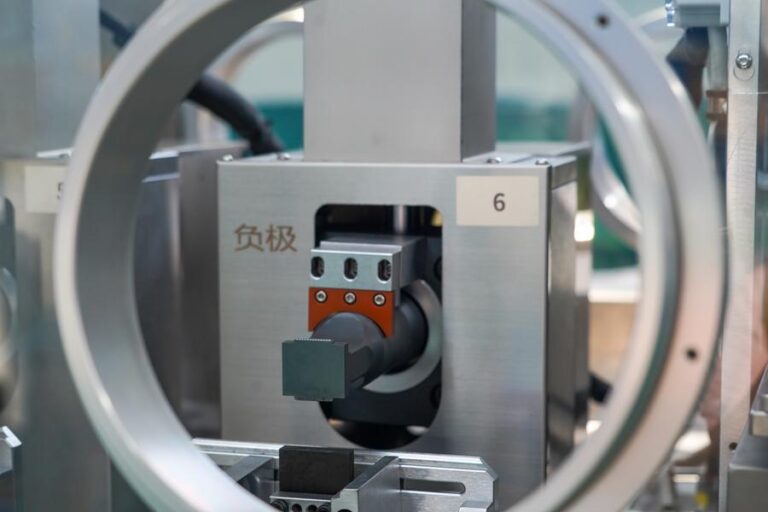

At the heart of a battery are lithium ions, which act like “deliverymen,” shuttling electrons between the positive and negative electrodes. The solid electrolyte serves as the “road” for these ions.

However, in conventional solid-state batteries, sulfide-based electrolytes are too hard, while lithium metal electrodes are too soft. When these materials interface, the uneven contact creates resistance, hindering ion movement and reducing efficiency — a long-standing bottleneck to commercialization.

To address this, Chinese research teams have developed innovative solutions that seamlessly bridge the gap between rigid and soft materials, ensuring smoother ion transport and enhanced performance.

One approach from the Institute of Physics, Chinese Academy of Sciences (CAS), uses iodine ions as a form of special “glue.” During operation, these ions migrate to the interface between the electrode and electrolyte, where they attract lithium ions to fill in microscopic gaps and pores.

This self-repairing mechanism creates a tightly bonded interface, effectively overcoming one of the most persistent barriers to the practicality of solid-state batteries.

Scientists at the Institute of Metal Research of the CAS have given electrolytes a “flexible transformation.” By building a polymer-based skeleton, they created a battery that remains fully functional even after being bent 20,000 times or twisted.

This design not only offers exceptional durability but also incorporates specialized chemical additives into the flexible framework — some to accelerate lithium-ion transport and others to capture additional ions — thereby increasing energy storage capacity by 86 percent.

In another development, a team from Tsinghua University has introduced a fluorine reinforcement technique. They modified the electrolyte with fluorinated polyether materials, leveraging fluorine’s high resistance to voltage to form a protective layer on the electrode surface. This fluoride-rich shield prevents the electrolyte from being broken down under high voltage.

As a result, batteries incorporating this technology have passed severe safety tests, including nail penetration and exposure to 120 degrees Celsius temperatures, without catching fire or exploding, thereby ensuring both high performance and safety. ■